Robots Play a Role in Industry 4.0

Manufacturers embracing the digital transformation and Industry 4.0 may see robots leading the charge when building a digital factory. The pressures remain the same for all Manufacturers: improve productivity, meet and/or exceed consumers’ expectations for customization and drive continuous product innovation. And of course, this must be done while consistently lowering costs. Measurable and meaningful progress is happening with Industry 4.0 in 2018. Industry 4.0 involves Manufacturers and the heavy use of automation and data exchange, by means of cyber-physical systems, the IoT and cloud computing, among others. With Industry 4.0, manufacturers will be able to operate “smarter” factories, in which they can more easily tailor products for specific customers. Many of the technologies being deployed today, such as big data/analytics, cloud services, and augmented reality, will also play a role in Industry 4.0.

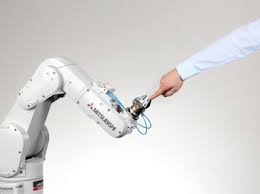

Robotics is part of the Industry 4.0 picture. The market for smart machines in the Americas, including autonomous robots, expert systems, and digital assistants, is growing and expected to greatly influence the manufacturing industry. Starting with the behavior-based robot, manufacturers can build behavior-based work cells, then factories. They can create intelligent portions of a line first, transition to an entire line, a collection of lines, a whole factory and then a collection of factories. You can see a version of a smart machine in most modern homes today. Personal drones, Google and Apple devices with digital assistants Alexa and Siri, are some of the most popular ones on the market today.

Some organizations tested out the use of robots in 2017 for various different tasks within the supply chain. One popular use was to perform predictive maintenance. Data captured from robots was used to indicate what is going to fail before it fails, allowing for downtime to be avoided, but also for maintenance to be performed only when it is absolutely necessary to production. Stopping downtime before it occurs is going to be a major part of Industry 4.0 and something that robots can play a role in.

Manufacturers that want to get in on the Industry 4.0 trend need to be looking at these technologies now and consider the shifts they will need to make. The revolution of things such as robots may be heavily relied on by Manufacturing and Supply Chain and you will need to ensure your business is staying on top of the digital revolution if you want any hopes of reaping the benefits that Industry 4.0 can offer. 2W Tech is a full service IT and ERP Consulting Firm and can assist you in your digital revolution journey. Give us a call today to get started.

Read More:

Inventory Management in Epicor Boosts Manufacturing

Tips to Make Your IT More Resilient

Building a Business Case for Business Continuity Whitepaper

Enjoyed reading this article? Click the button below to download this asset.

Download “Business Continuity Whitepaper” Now

Building a Business Case for Business Continuity

Please complete the form to download the file.