Epicor Product Data Management Tool

With manufacturers fielding data from every nook and cranny of its operations, it can be overwhelming to analyze everything to make sure your business is at its most efficient. When you set up your business with Epicor’s ERP system, you can have the company’s powerful Epicor Product Data Management tool at your fingertips, ready to bring your data together in one simple dashboard. Epicor Product Data Management serves as a central knowledge repository for process and product history. PDM promotes integration and data exchange among all enterprise users who interact with products — including project managers, engineers, salespeople, buyers and quality assurance representatives.

Epicor offers a solution that manages the powerful information traditionally contained in engineering documents, plant floor routings, change orders, sales orders and quality documentation within a single solution that is easily shared across the enterprise. Promoting collaboration throughout the value chain, Epicor PDM provides a complete end-to-end solution to manage all aspects of a product’s lifecycle, enabling enterprises to control the enormous amount of electronic documents they produce.

PDM takes control of these electronic documents:

- Bill of Materials (BOM) — Epicor supports traditional BOM management with single-level part formats that recognize the materials and components required to build end parts. In addition, Epicor introduces multilevel BOM management that incorporates not only single-level components and material requirements, but also internal and external routing steps for complete end assembly visibility, planning, scheduling and costing.

- Routing — Detailed routings facilitate planning, scheduling and costing of products more efficiently. Managing changes to routings is simplified. Changes are automatically communicated to the plant floor execution system and operators have online visibility of the latest routing production notes as well as standards and resource requirements.

- Engineering Change and Revision Control — This is designed to enable engineering change management, multiple revision control of products, engineering workflow management and offers detailed cost analysis of products during the engineering process.

- Product Lifecycle Management — This serves as a central knowledge repository for process and product history, and promotes integration and data exchange among all enterprise users who interact with a product. Epicor PLM manages all documentation associated with a product throughout its entire product lifecycle, and includes full integration with more than 12 computer-aided design systems as well as various electronic design automation systems.

- Product Configuration — This enables on-the-fly configuration of highly customizable and dimensional products via a straightforward question-and-answer evaluation. Product Configuration can be accessed from quote entry, order entry and job entry. It is Web-enabled, and is available to users employing Commerce Connect.

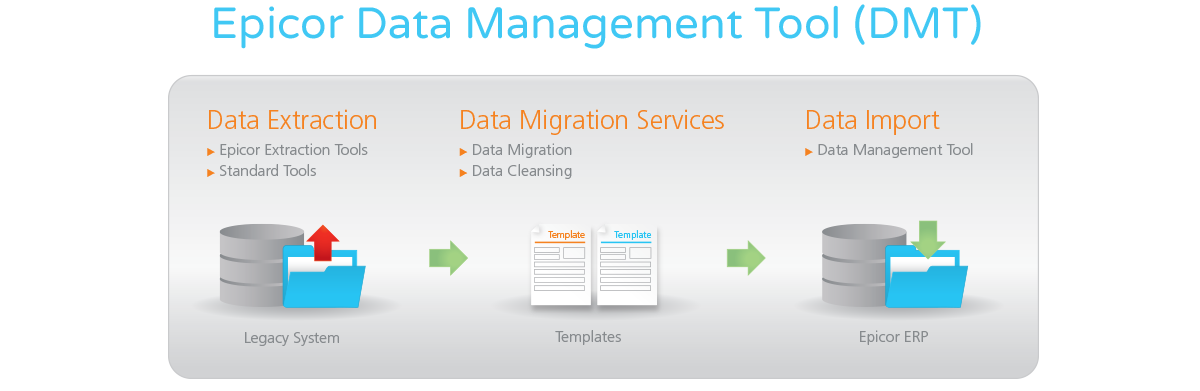

The data your operations automatically create are invaluable to your business. When using Epicor’s data management tool, the data becomes your weapon for successful production. Contact 2W Tech today to see how you can best utilize Epicor’s data management tool for your company.

Read More:

Combating Cyberattacks with Disaster Recovery

Microsoft Azure Databricks

Best Practices for ERP Success Whitepaper

Enjoyed reading this article? Click the button below to download this asset.

Download “Best Practices for ERP Success” Now

Best Practices for ERP Success Whitepaper

Please complete the form to download the file.