Do you need MES Software?

Before you can know if you need it, you need to understand what it is. Manufacturing Execution Systems(MES) are computerized systems used in manufacturing to track, control and document the transformation of raw materials to finished goods. In manufacturing, your money is made on the shop floor. MES provides information that helps manufacturing decision makers understand how current conditions on the plant floor can be optimized to improve production output. The system works in real time and gives visibility into multiple resources thoughtout the production process such as material, personnel, machines, and support services. I am trying to explain MES in simple terms, but the reality is the system performs complicated tasks and simplifes your manufacturing process way easier than you could manage without it. The manufacturing process for each individual item or lot is tracked from start to finish and documentation of each step is available for analysis.

MES system also manages:

- process definitions

- resource scheduling

- job execution and dispatch

- data collection and analysis

- equipment downtime

- product quality control

- materials track and trace

- reporting of metrics

- device history record

So now that you have a glimpse of what MES is, the question is do you really need it? MES systems at the most basic level increases visibility and transparency into every aspect of your manufacturing. This system is designed specifically to manage the shop floor and you will be hard pressed to find another type of system that can get as granual with these processes. MES can help your organization:

- Reduce production errors

- Decrease part lead time

- Increase productivity

- Improve quality compliance

- Reduce quality losses

- Increase production throughput

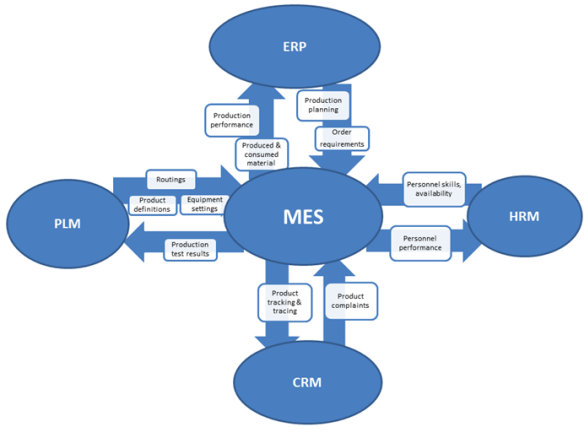

So you need to ask yourself, do you have an alternative method to achieve these things? ERP systems are the technology heart of your business and that will not change anytime soon. MES systems can strengthen your heart. MES and ERP systems can be integrated together giving you the best possible technology scenario as a Manufacturer. MES software can be tailored to meet your specific requirements and interface with your ERP software to integrate the critical data. Necessary information from your shop floor will be passed back and forth between your ERP system and your MES software.

The manufacturing industry is going to continue to get more complex and complicated. As you continue to need greater control, compliance, time-to-market, and visibility for managing product lifecycle execution with accurate instructions, real-time data, and manufacturing intelligence, you are most likely going to need AND WANT an MES.

Read More:

Implement Cloud ERP Today

Where is Your Data?

Profitable Growth in Manufacturing

Enjoyed reading this article? Click the button below to download this asset.

Download “Profitable Growth in Manufacturing” Now

Profitable Growth in Manufacturing Whitepaper

Please complete the form to download the file.